LMAS conducts research in sustainable manufacturing with respect to economy, society and environment

Data Analytics for Smart Manufacturing

With the increasing availability of sensors and sharp decrease in computation costs, data-driven decision making in manufacturing systems is quickly becoming feasible. LMAS dives deep into "data-driven manufacturing" and is involved in analysis of big data for multiple projects. Data can be collected in manufacturing systems at multiple levels, from the system-level to the operation-level with varying degrees of complexity. LMAS strives to overcome the challenge of processing this large amount of data into useful parameters for process optimization. LMAS analyzes these vast datasets to aid manufacturing enterprises in informed decision making in terms of economic, environmental and social sustainability

Green material selection for manufacturing

New legislation, growing consumer awareness, and broad industry led sustainability initiatives have motivated individual companies to address the negative impacts associated with chemicals in their products and supply chains, including both upstream and downstream activities. The goals of this project are to identify substances used in electronic equipment that may have a negative impact on the environment and/or human health, to provide alternative material assessment, and to evaluate tradeoffs between material selections, in order to support decision making at the design phase of the product life cycle. An effective assessment of these impacts benefits from the holistic approach offered by systems thinking. This approach considers impacts in the context of the whole system, rather than evaluating each in isolation, ensuring that an improvement in one part of the system does not have negative consequences elsewhere in the system

Appropriate manufacturing technologies for emerging economies

Many countries throughout the world lack thriving manufacturing sectors, leading to suppressed economic development. Large-scale manufacturing can unlock a country’s potential by lowering product costs, providing employment opportunities, and leading to the creation of auxiliary services. But for countries with limited resources strategic choices around industry development have to be made, in order to ensure that such investments will prove beneficial in the long run. Too often countries spend money on initiatives and infrastructure that will never make them money. LMAS seeks to (1) identify factors inhibiting productivity in developing countries (2) characterize social impacts in the context of manufacturing (3) design strategies for manufacturing of appropriate technologies and (4) determine mechanisms by which countries can achieve industrialization in light of water and energy constraints.

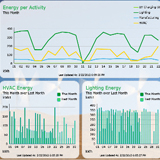

Development of energy metrics for smart manufacturing

Engineers play a vital role in sustainability. Designers and manufacturers have unique control over sustainability by having a direct impact and control in the amount of resources (e.g., electricity, water, and materials) consumed throughout a products lifetime. To continue to make products and their manufacturing as sustainable as possible, we are using a combination of big data, applicable sustainability metrics, and manufacturing taxonomy to incorporate real-time diagnostic and prognostic improvements into dynamic manufacturing. We must consider what inputs and outputs are the top priorities, why these are the priorities and what metrics must be evaluated to achieve the best balance of inputs and outputs. With these tools we will have the ability to increase the efficiency and sustainability of the engineering process; from design to manufacturing

A Total Cost of Ownership Model for Design and Manufacturing Optimization of Fuel Cells

This is a project funded through the DOE in which a team compromised of LMAS, UC Berkeley, and LBNL researchers have partnered to create a total cost of ownership model for various types of fuel cells. Costs associated with design, manufacture, assembly, and balance of plant components are the underlying contributors to the model. Furthermore, this project incorporates a life-cycle impact analysis that quantifies the environmental benefits of the adoption of fuel cells.

Joint Center for Artificial Photosynthesis

The Joint Center for Artificial Photosynthesis (JCAP) has been charged with creating a photoelectrochemical (PEC) solar fuel device. The technology generates hydrogen and oxygen gases by splitting water in a cell using only sunlight as an energy source. This carbon neutral system will use the hydrogen generated as a fuel source. The PEC is composed of a chassis, a window, an active area, and plumbing. The chassis provides the structure to contain and support the other components. The window allows light to enter the active area and initiate the reaction while protecting the cell from outer impacts. The active area contains the membrane, catalyst, and light absorber (i.e., photocathode, photoanode, or a combination of the two), which generate and separate the products (i.e., hydrogen and oxygen). The plumbing provides the reaction with electrolyte as needed and transports the products out of the active area. Researchers are currently facing the challenge of creating PEC devices that are cost effective, efficient and scalable. Manufacturing, testing and evaluating prototypes provides experimental feedback for future designs.

Design for Sustainability

- Noble, J., Walczak, K., and Dornfeld, D., “Rapid tooling injection molded prototypes: a case study in artificial photosynthesis technology,” Procedia CIRP, Volume 14, 2014, Pages 251-256, ISSN 2212-8271

- Bochmann, L., Bayley, C., Helu, M., Transchel, R., Wegener, K., and Dornfeld, D., “Understanding Error Generation in Fused Deposition Modeling," Surf. Topogr.: Metrol. Prop., 3, 2015, 014002.; (also appeared as Bayley, C., Bochmann, L., Hurlbut, C., Helu, M., and Dornfeld, D., “Understanding Error Generation in Fused Deposition Modeling,” 2014 Spring Topical Meeting of the American Society for Precision Engineering: Dimensional Accuracy and Surface Finish in Additive Manufacturing, Berkeley CA, April, 2014.)

- Clemon, L., Krishna, A., Sudradjat, A., Rammah, M., Jaquez, M., and Dornfeld, “Precision and Energy Usage for Additive Manufacturing,” Proc. ASME 2013 International Mechanical Engineering Congress and Exposition, IMECE2013 November 15-21, 2013, San Diego, California, USA, IMECE2013-65688

- Eggleston, J., Walczak, K., and Dornfeld, D., “Rapid Design and Fabrication Methodology for Moldable Materials Used In Artificial Photosynthesis,” LMAS Research Report, November, 2013.

- Wolf, R., “Optical Prototype Design for Artificial Photosynthesis Technology Manufactured by Injection Molding,” M.S. Thesis, LMAS Research Report, May 30, 2014.

- Faludi, J., Bayley, C., Bhogal, S., Iribarne, M. "Comparing Environmental Impacts of Additive Manufacturing vs. Traditional Machining via Life-Cycle Assessment." Rapid Prototyping Journal, Vol. 21 Iss. 1, pp.14-33 2015.

- Faludi, J., Hu, Z., Alrashed, S., Braunholz, C., Kaul, S., Kassaye, L. "Does Material Choice Drive Sustainability of 3D Printing?" International Conference on Mechanical Engineering and Manufacturing, Istanbul, Turkey, Feb 17 2015. (Published in International Journal of Mechanical, Aerospace, Industrial and Mechatronics Engineering Vol:9 No:2, 2015).

- Faludi, J., Ganeriwala, R., Kelly, B., Rygg, T. F., Yang, C. "Sustainability of 3D Printing vs. Machining: Do Machine Type & Size Matter?" Proceedings of EcoBalance Conference, Tsukuba, Japan, Oct 28 2014.